Model No.︰128713K

Brand Name︰Monton

Country of Origin︰China

Unit Price︰CNY ¥ 60000 / pc

Minimum Order︰1 pc

| Material: | 55SiMoVA Or G20CrNi4A | Row: | 8Row Or 10Row Or More |

|---|---|---|---|

| Types: | Thrust Angular Contact Ball Bearings | Bearing Life: | 200 Hours |

| Application: | Drilling Motor Or Downhole Motor | Customer: | Oil Drilling Industry |

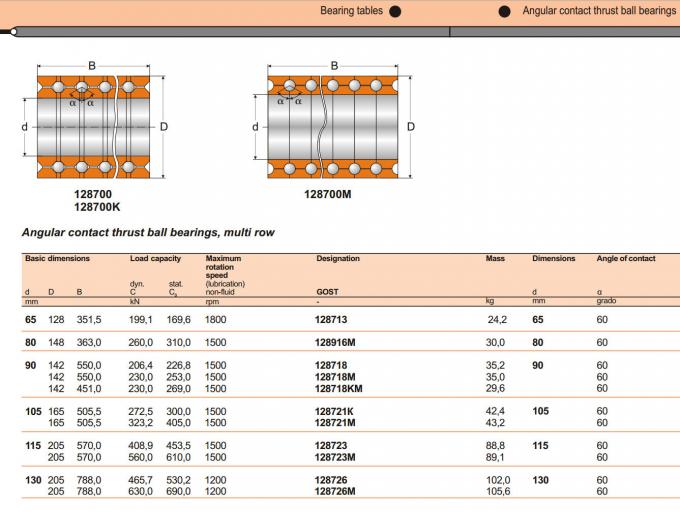

Thrust Angular Contact Ball Bearing For Downhole Drilling Motor

Mud Stack Thrust Bearing for Downhole Drill

128713K

65*128*351.5mm

Application:Downhole drilling motor

Main customers:SLB,GE,etc

This kinds bearings working together with TC bearings in the downhole motor.

Product Description

The bearings in a mud motor at the end of a drill string would place a huge influence on productivity and reliability in terms of oil

drilling or gas drilling.The working condition of these mud motor bearings are extremely harsh: the bearings bear heavy axial and

shock loads, and they are also exposedwith highly abrasive mud.

• Special steel for all bearing components

• Full complement bearing

• Precision matched rings

• Unique bearing design to support heavy

• axial drilling loads

Bearing Assembly of Downhole Motor is used to transmit motor rotary dynamic force to the bit, meanwhile to withstand axial and radial load from drilling weight. Inside of the Bearing Assembly,Monton uses TC Radial Bearing and a stacked thrust bearings. The thrust bearings support the downward force resulting from the “weight on bit” (WOB) and the loads from the combination of hydraulic thrust and weight loads from internal components.Monton provides different bearing assemblies, designed to meet the diverse requirements of the drilling industry.

1) Bit nozzle pressure loss is 7.0 Mpa, Monton uses a stacked multiple balls design for the thrust bearings. The thrust bearings support the downward force resulting from the “weight on bit” (WOB) and the loads from the combination of hydraulic thrust and weight loads from internal components.

Rolling Element Bearings (Ball Bearings)

Rolling element bearings, or ball bearings, have conventionally been used to react thrust, or axial, loads in downhole mud motors. When low rpm power sections are used in the application such bearings provide suffcient life and reliability. However, bearing component fatigue causes life to decrease linearly as speed increases; fatigue makes ball bearings unsuitable for high rpm motors. In addition to life, friction and horse-power losses are often of interest in drilling. Ball bearings are referred to as frictionless bearings due to the rolling nature of the elements; however in practice frictional losses exist duo to rolling resistance and sliding. An order of magnitude approximation of the coefficition of friction (CoF) for an angular contact bearing operation in ideal non-abrasive lubricant conditions is 0.0032. In drilling mud, the CoF can be assumed to be significantly higher.

Payment Terms︰ T/T